PIPE THREADING MACHINE

Product Details:

- Material Stainless Steel Alloy

- Computerized No

- Control System PLC Control

- Surface Treatment Nickel Plating

- Feature Simple Control

- Warranty 6 Month

- Click to View more

PIPE THREADING MACHINE Price And Quantity

- 10000.00 - 50000.00 INR

- 1 Unit

PIPE THREADING MACHINE Product Specifications

- 6 Month

- No

- Nickel Plating

- Stainless Steel Alloy

- PLC Control

- Simple Control

PIPE THREADING MACHINE Trade Information

- Cash on Delivery (COD) Telegraphic Transfer (T/T) Cash in Advance (CID) Cheque Cash Advance (CA)

- 2000 Unit Per Month

- 1 Week

- All India

Product Description

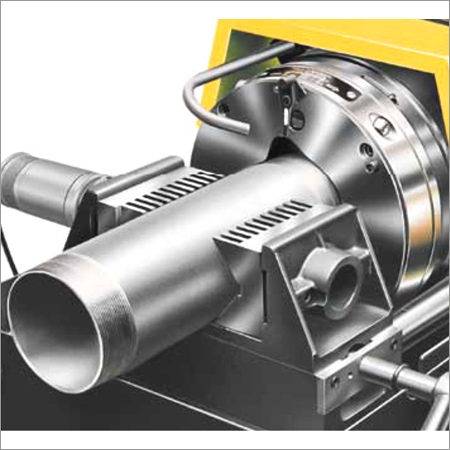

UNIMAT 77

Semi-automatic high-performance machine for efficient cutting of pipe threads. For industry, metalworking,installation.

Features

- REMS Unimat 77 - pipe threads up to 4".

- Tangential-chaser-threading-system. Fast working, short resetting time.

- For single and series production.

Operating principle

Stationary material- rotating die head.

Execution

Compact, rugged design for continous use. Die head with regrindable tangential chasers in self centering holder system. After start-cutting with feed lever and rack mechanism self feeding action of die head (no guide thread). Welded, sturdy machine stand with large oil compartment and removeable chip drawer.

Drive

Robust worm gear and 2-stage spur gear. Proven and powerful pole-reversible three-phase motor, specially designed for threading, 2000/2300 W. Overload protection. Reverse switch for cutting right and left-hand threads. 4 spindle speeds 50, 25, 16, 8 rpm.

Clamping device

Self-centering universal vice for the complete range with specially toothed and hardened clamping jaws (2 sets). Optional manual or hydraulic/pneumatic clamping with foot switch (working pressure 6 bars).

Automatic lubrication and cooling

Robust, proven oil pump with high pumping volume. Ample oil volume ensures longer life of chasers, gear and motor.

Universal automatic die head

Only one universal automatic die head for all threads. Fine adjustment of thread diameter with spindle and scale. Die head closes automatically and opens automatically when the required thread length is reached. After starting the thread via feed lever and rack the chaser-system initiates an automatic feed-forward of the die head. All threads can be cut in a single pass. Copying unit for tapered threads. Instead of changing the dies, additional quick-change die heads ensure shorter resetting time.

Chasers

The proven regrindable REMS tangential chasers with precise cutting geometry ensure an excellent start-cutting performance and clean threads. Tool steel chasers made of special hardened steel for material up to 500 N/mm2. HSS chasers for hard-to-machine material above 500 N/mm2. The chasers sit in a special holder system. Chasers and holders together form a threading set.

Technical Specifications

- REMS Unimat 77-manual clamping device & REMS Unimat 77-Hydraulic/pneumatic clamping device.

- Semi-automatic threading machine for pipe threads 1/4 - 4".

- Thread length:< 200 mm

- Chamfering

- Range: 7-115 mm

- Chamfered : 7 mm

- Maximum chamfer: 7 mm

- Chamfer angle 45o

- Machine on stand. Pole-reversible 3~ induction motor with hollow shaft, 400 V, 50 Hz, 2000/2300 W, right and left-hand rotation. Die head speed 50, 25, 16, 8 rpm.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Other Products in 'Pipe Threading Machine' category

|

PIONEER INTERTRADE PVT. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |